Butternut HF9V Installation

This is a duplicated article from the original one I posted to slepp.ca about the Butternut HF9V Installation. I’m putting this as a bit of a placeholder for now.

Deciding on an Antenna

I live on a fairly small lot in Edmonton, AB, CA (grid square DO33gn, for those that are curious). The problem with this sort of lot is there is no space for a large HF antenna. This leaves the options of what to put out in the yard for long distance communications something that is vertical. Dipoles are nice and simple to build, they have good coverage and other useful aspects, but they are also (in general) huge. Since anything that is parallel to the ground is limited by the boundaries of my lot, a larger dipole than one built for 20 metres is not really practical. When using a vertical antenna, it just has to go straight up and not use a lot of ground space. This allows for a much larger or complicated antenna than would otherwise fit.

I spent a few months looking around at various antennas and designs and made my final decision to pick up the Bencher Butternut HF9V. Though expensive, it had good reviews, would fit nicely into my yard and still be shorter than my house, and I have to admit it looks quite amusing and impressive to me. (My neighbour returned home while I was erecting the base of the antenna and she was really caught off guard by the appearance.)

I ordered the antenna originally from Bencher themselves, but they were backordered. I went ahead and ordered it from HRO instead as they had them in stock.

A Package Arrives

Tuesday afternoon a package arrived from Ham Radio Outlet. It was the Butternut HF9V I had ordered two weeks earlier. For the low, low cost of about $495.00 USD, you too could own one of these antennas. Sure, it is fairly expensive, but I’m pleased with the results after just my first night of testing.

This post is all about the assembly of the antenna and the initial phase of tuning it up. As for the amount of time it took to get from unpacking it to using it on the air, the total time was about 4 hours - including the time spent driving the support rods into the ground. The antenna comes in a very compact box which I found easiest to unpack by simply tearing all the cardboard to pieces.

Unpacking

After it was unpacked, the main parts of the antenna like the coils and tubing were easy to see. The rest is in the cardboard rectangle. In that piece, you’ll find all of the nuts, bolts and other gadgetry needed to put the antenna together. You may notice I’m putting this together on my living room floor. Keep in mind that the full length of the antenna is 26 feet, so indoor assembly may not always be an option. It does primarily go together as two long segments, but the one is easily 15 feet long (the upper section) and needs to be put together in one piece to run some wires on.

Starting to Assemble

The manual is reasonably clear on the steps, just not always reasonably clear about identifying the part you want to work with. It has a diagram of all the parts on one sheet with their letter designators that are used throughout the assembly instructions. One common complaint I saw from other users of this antenna was the lack of diagrams in the manual. Overall, it wasn’t all that bad, but a few images (at all) during the instructions phase would be most helpful in ensuring you put the right pieces in the right places.

The image is after placing the 80/40m coil onto the main tube. The main tube is actually split into two pieces (known as B and B1 in the manual). They are split by a piece of fiberglass rod which is where the centre clamp of the 80/40m coil assembly attaches. This step was really quite straight forward. Measure, align and use the wing nuts to tighten the coil ends. The extended coil in the image is the 40m coil.

There’s another photo of the 80/40m coil from after stretching out the 80m coil.

Capacitors

This antenna uses two capacitors, a 200pF and a 67pF, to provide matching on 80m and 40m. They were really straight forward to assemble. However, attaching their brackets to the main tube was actually a bit tricky to keep everything in alignment. Being a bit of a perfectionist for things being straight, I spent some extra time here I probably really didn’t need to.

30m Coil

The 30m coil is the strangest attachment to the main tube in the kit. It attaches to the fourth turn of the 40m coil and the main tube via an arm with an embedded capacitor. You can see a close-up of the assembly in the first image below. Attaching it to the coil and the main tube took a little wiggling around to get it over all the bumps and curves. A little bit of the anti-oxidant paste on everything and it was bolted in place. At this point, it’s starting to look quite a bit like the photos and diagrams of the antenna.

17m and 12m Coils and Crossbars

The 17m and 12m coils have metal strips along their tops. They attach with nuts and bolts that are already on the coil assembly out of the package. The two coils are very close in size, but the 17m is larger by a few turns. The 17m strip is substantially larger than the 12m strip. You can tell that this is the comparison from the diagram in the assembly insructions.

I took a photo of the two coils side by side to show the difference. The right hand coil is the 17m coil. I found that attaching the two strips, it was hard to get them to stay perpendicular to the coil body and insulation arm. In the end, I just adjusted the angle after the entire antenna was assembled and in the air.

The photos below show the two coils attached to the main antenna tube.

Completion of the Lower Segment

From the beginning, the 80/40m coil went on first, then the 30m attached to the 40m coil and the main tube, then the 17m and 12m coils and their metal strips. At this point, the entire lower assembly is completed and in one piece. I tightened up all the bolts and wingnuts to keep things secured after having checked that it was all looking put together correctly. In the photo, you can also see the beginnings of the upper half of the antenna on the left. It has one of the insulation arms attached to it at the bottom.

Wiring up the 15m and 6m

Attaching the loose wires for thr 15m and 6m sections was not very hard at all. It is just a long segment of the antenna to work with. It took up my entire living room in length and a little bit of the dining room. The insulating brackets weren’t critical on their positioning and with the wire being single-ended, the position of the attachment bracket was the only thing to really measure.

There was an instruction to measure 11ft 3in from the attachment of the longer wire and to make sure the lower bracket for that wire was positioned far enough up the mast to show the mark through. I have yet to figure out why this isn’t required on the shorter wire.

(The astute observer may notice the Parrot AR.Drone box in the background. It’s a video camera equipped quadcopter that is flown by using a mobile device like an iPhone. You can then record videos and share them around. See my helicopter hobby pages for some information on mine.)

Getting it Raised

Getting the antenna outside was, thankfully, straight forward by nature of being a straight line from the living room to the back yard. It would have been impossible to get around any corners with the antenna’s upper section. The lower section was small enough to stand up and walk around with.

The very first instruction in the assembly manual is to install the mounting post into the ground and attach all the ground radials. I skipped that step since I was just going to assemble the antenna on my floor. At this point, I gave a go at driving the 2 foot post into the ground. In the photo you can see the fiberglass insulator at the top of a very short piece of metal. The other two feet of it are underground now. Closer to my foot, and right next to the flag and pretty dandelion, you’ll find the 8 foot ground rod I had previously driven into the ground while waiting for the antenna to ship.

The entire antenna is supported by one bolt on the upper part of the fiberglass insulator. The other bolt is the ground and shield connection for the radials and coax. The lower section of the antenna fits snugly around the fiberglass base and is really easy to put together. The assembled mast is very lightweight and easy to handle at the short length. This becomes another story when it comes to putting on the top half of the radiator.

In the photos you’ll also find the piece of wood I used to keep the fiberglass rod from being damaged by the hammer and the axe I was using to cut 2 inch deep lines through the grass to run the ground wires.

Attaching and Running the Radials

According to Bencher and many others, a vertical antenna is only as useful as the quality of the ground radials attached to it. You can read reports of people using anywhere from 4 to 120 radials. (I’m sure there are some that use even more.)

I had decided that the easiest way to get started on my ground radials was to order the Ground Radial Kit from Bencher along with the antenna. It comes with about 360 feet of wire cut into 12 strands and terminated in ring terminals. I used a little bit of the anti-oxidant paste on the bolt where these would be attached. First things first, I attached the coax shield to the lower bolt, then the lower half of the matching coil, followed by a washer and then all 12 of the ground radial terminals. This little setup took every last bit of the bolt to fit. I tightened the bolt down while holding most of the terminals in place to create a bit of a star pattern coming out of the attachment point. This would later help in laying them out in useful angles from the base.

The upper bolt which was used to attach the antenna itself to the fibreglass insulator for the mounting post protrudes far enough to attach the other half of the red matching coil and the centre conductor of the coax. The coax is supplied with the antenna as it is an impedance matching section. At the far end of that coax (which is only about a dozen feet long) is a PL-259 and SO-239 coupler. The end of the coax looks well sealed around the braid, which was initially one of my concerns until I looked closer at it.

I straighted out and uncoiled all of the ground radial wire after attaching it to the post. At around 30 feet long each, they extended well into my neighbour’s backyard. Conveniently, being a new house on that lot, the fence was torn down during demolition of the previous house. That gave me a fair bit of room to work with in laying out the wires and getting things sorted out.

It took a little while to get all of the radials in a nice pattern that appeared to be reasonably well spaced (photo on the left). Unfortunately, my backyard is not very large, so beyond this point near the base, the radials start to curve around all sorts of objects. I’ll be spending a few days getting those all sorted and aligned, I’m sure.

Attaching the Upper Segment and Completion

It turns out that I had nothing tall enough to really reach the top of the base antenna to attach the upper segment. I ended up finding a frighteningly rickety wooden ladder from my neighbour and gave it a go. I nearly fell off a few times (only a few feet in the air) since the top half of the antenna is very bendy and liked throwing its weight around. Having to extend my arms and align it with the top of the lower mast took quite some effort and time. In future, I would rather find a ladder that goes perhaps 10 feet into the air to let me comfortably work at the union between the two antennas. I may yet need something that tall to work on the upper bands tuning.

The pictures below weren’t necessarily taken in order of the build, but they all show the antenna at its full height and with everything attached. At 26 feet, this antenna is a monster in my backyard and rivals the height of my house. (Unrelated, that ladder in the background leaning against the house fell down in the severe windstorm that was to follow putting up this antenna. Note to others: Tie down your ladders at the top if possible.)

You can see in various photos that part of the positioning problem for this antenna was the proximity of overhead power lines. I placed the antenna as far as reasonably possible from these lines and then guyed it in such a way that it will have great difficulty falling anywhere near the lines. If it falls down, it will end up in the tree or on my deck before it heads toward the power.

Post Installation Storm

Below is the section of tuning I managed to get before the weather turned superbly ugly. It started to hail, severe thunderstorms and heavy rains. I only had enough time to collect my tools and clean up a little before I was drenched. The goods news is, the guying and antenna structure was sound, which the storm helped me see clearly by seeing how far the antenna would deflect in the wind and to see that the guying was keeping it from bending too far toward the power lines.

Initial Tuning Results and Trial

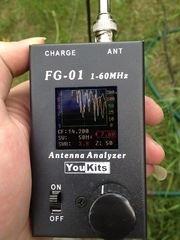

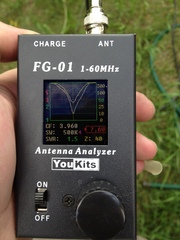

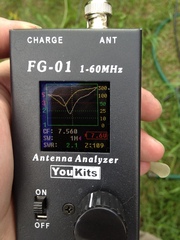

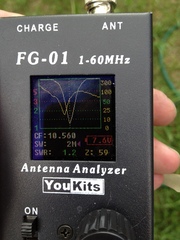

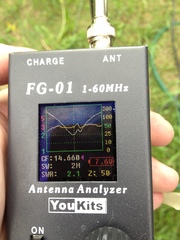

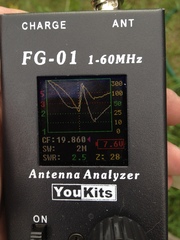

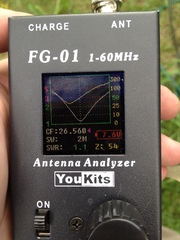

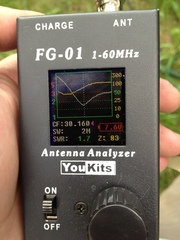

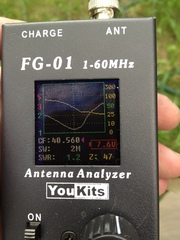

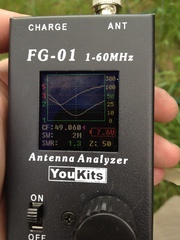

Below are all the images I took of the antenna analyzer (a YouKits FG-01). Due to the large storm that boiled its way into town shortly after these photos were taken, I was only able to really tune up the 80m segment of the antenna before I had to go inside. The 80m segment managed to be tuned to 1.6:1 with around a 50-80kHz bandwidth just by moving the coil around a little. I plan to tune up all the elements, but you can see that overall, the antenna was reasonably close to being useful on all the amateur bands as assembled.

I later used the antenna with an MFJ tuner on 14.070 MHz to talk to a fellow from New Zealand for an hour or so (using Olivia 6/500) with just 10W of power. The antenna made a stunning difference in the amount of noise I was receiving on my rig compared to my homemade 20m dipole hanging just feet away. All in all, for the complete lack of a good ground radial system (they are still just sitting on top of the grass right now) and no tuning, it performed extremely well.

Conclusion

Basically, I’ve only had the antenna for one day, but I have already talked further than ever before and heard more traffic on the air than ever before. That was the goal of the project and I’m happy to report it seems to have worked out. I’ll post again about the tuning results and further performance reviews.

In the meantime, you may wish to see the rest of my hobbies or more about my amateur radio hobby.